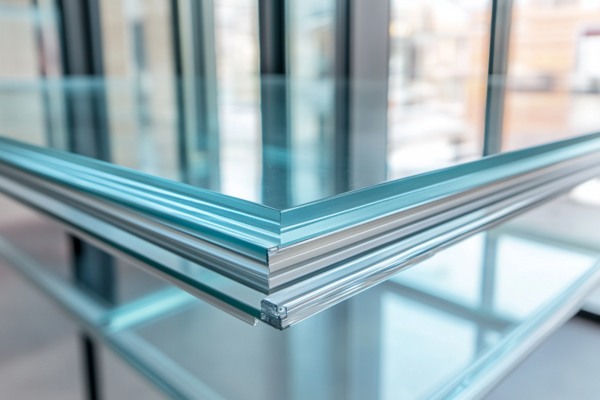

In the world of glass solutions for architecture and design, different types of treated glass are used based on structural, safety, and aesthetic needs.

Two specialised types of glass, heat-strengthened and heat-soaked glass, are engineered to meet demanding architectural needs. Both offer unique properties and strengths and are chosen for specific applications.

Let’s dive into these types of glass, their benefits, and common uses.

Durability and Clarity Combined

Heat-strengthened glass (HS glass) is a type of glass that undergoes a controlled heating and cooling process, giving it strength superior to standard, annealed glass. The key lies in the cooling method used:

Heat-strengthened Glass Stands Strong in Style

Promising Safety and Resilience

Heat-soaked glass refers to fully tempered glass that undergoes an additional heat treatment to minimise the risk of spontaneous breakage caused by NiS (Nickle sulfide) inclusions. This inclusion can sometimes expand after the glass is installed, leading to sudden breakage, which is especially undesirable in high-stress environments like tall buildings.

The heat-soak test process involves:

Safety comes first with Heat-Soaked Glass

The choice between heat-strengthened and heat-soaked glass depends on the project’s specific needs and requirements:

Saint-Gobain’s glass solutions offer resilience, safety, and design flexibility tailored to the demands of today’s architectural challenges.

What is the difference between heat-strengthened, annealed, and tempered glass?

Annealed glass is a standard glass with lower strength than heat-strengthened and fully tempered glass. Heat-strengthened glass is twice as strong as annealed glass. When heat-strengthened glass is impacted, it tends to crack into larger pieces, while annealed glass shatters into long, sharp shards, posing a safety risk. However, tempered glass is the strongest of the three, with remarkable strength and breaks into small, rounded fragments upon significant impact, reducing the risk of injury.

What is the difference between heat-soaked and toughened glass?

Heat-soaked glass refers to fully tempered (toughened) glass that undergoes an additional testing process to identify any impurities. Glass panels that contain nickel sulfide (NiS) inclusions are more likely to break during this process. Toughened glass, also known as tempered glass, is a type of annealed glass that is strengthened through heating and rapid cooling, making it more durable and impact-resistant than annealed glass.

Will the heat soak process prevent the toughened glass from breaking?

The heat soak process is an additional heat treatment measure that helps reduce the risk of spontaneous breakage in tempered glass in the future.

Jahanavi Arora is an architect by profession and a writer by choice, with over 7 years of experience in architecture and design writing. Read More